Precision Plastic Injection Parts

Advantages of YUNYI's Precision Plastic Injection Parts:

1. Flexible and smart design in molding equipment.

2. Short lead time and high injection accuracy by high-tech automatic injection machine.

3. High reliability and strong durability ensured by strict control on supply of plastic materials and metal plate.

4. High product quality and low failure rate ensured by complete quality control system.

5. Complicated solutions for quick delivery.

R&D and Production Capability:

1. More than 50 professionals with long-time experience in manufacturing and processing molding equipment.

2. Precision process design and flow process are adopted to ensure the processing quality.

ERP+APS+MES+WMS production management system is adopted to assure effective production management and timely delivery.

3. More than 60 advanced molding equipments (including horizontal injection molding machine & vertical injection molding machine)

4. More than 30 experts are employed by YUNYI to design the process of insert stamping and plastic injection.

5. More than 30 technicians committed to developing high precision molding frame with more than ten years experience.

Application:

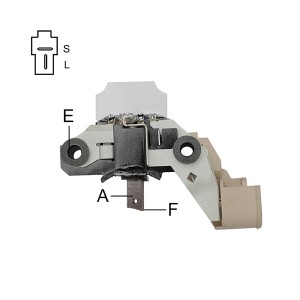

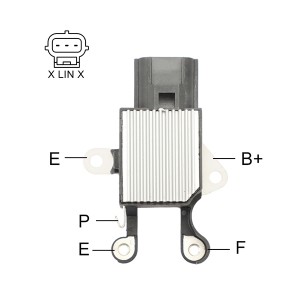

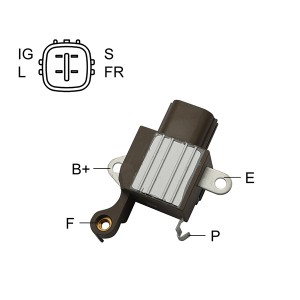

1. Vehicle voltage regulator housing

2. Alternator rectifier lead frame

3. Protective cover on alternator

4. Vehicle voltage regulator housing brush holder

5. Motor inner gear ring

6. Slip ring

7. Wiper blade

Materials:

PA66, PA6, PBT, PPS